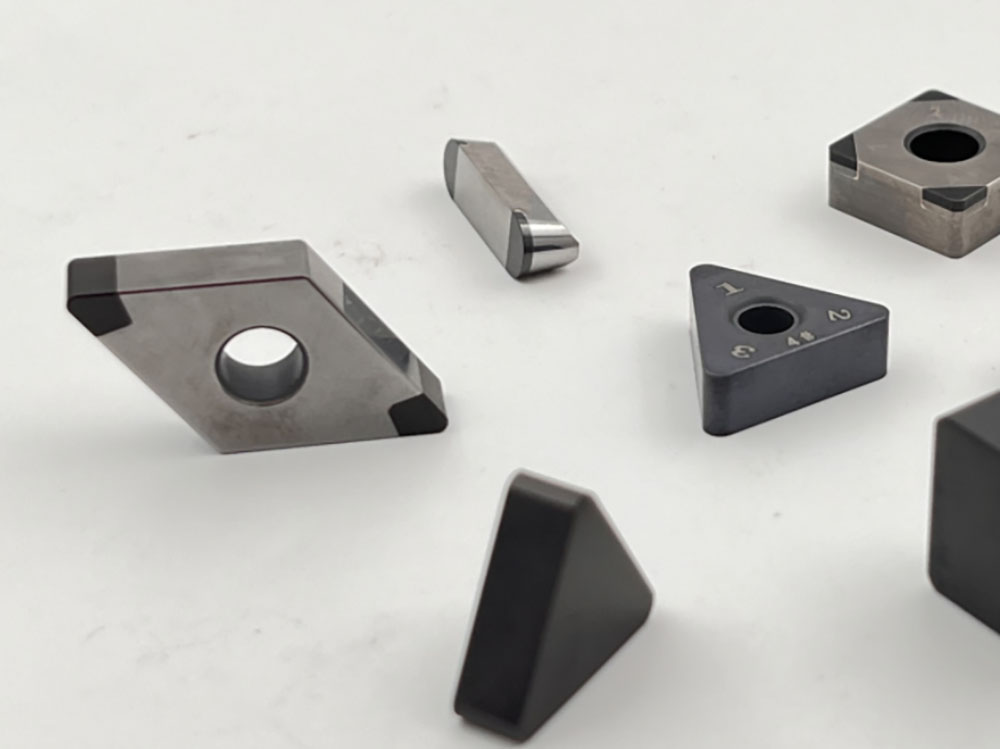

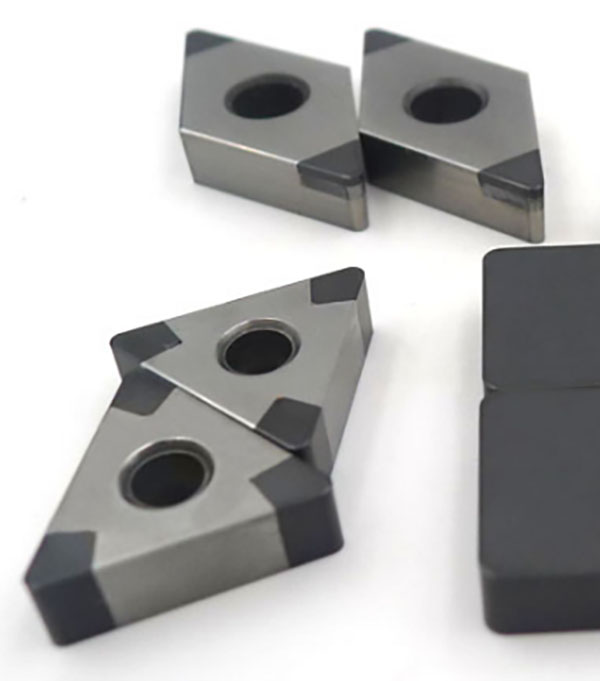

Héich Qualitéit verschleißbeständeg polykristallin Diamant Toolblade a CBN Insert

CBN Inserts hunn héich thermesch Konduktivitéit an héich Stabilitéit, wat hinnen erlaabt hir Eegeschafte bei Temperaturen bis 1400 ° C ze halen, wou Diamanten iwwer 800 ° C zersetzen.CBN Inserts si gëeegent fir High-Speed-Schneiden a Veraarbechtung vu High-Nickel- a Chromgoss, Autosbremsscheiwen, Bremstrommelen, Goss-Nubs, Gossrollen, Roller a Pompelen, etc. Liewen a reduzéieren machining Käschten.

Produit Virdeeler

D'Mikrohardheet vum CBN Eenkristall ass HV8000 ~ 9000, an d'Härheet vum PCBN Composite Blat ass allgemeng HV3000 ~ 5000. Dofir huet et méi héich Verschleißbeständegkeet wéi hart Legierung a Keramik beim Veraarbechtung vun héich härte Materialien, a kann d'Gréisstabweichung an Deeler reduzéieren Veraarbechtung.Et ass besonnesch gëeegent fir Ausrüstung mat héijen Automatisatiounsgrad, a kann d'Auxiliary reduzéieren

| Form setzen | Typ | Grad | |||||||

| d | s | d1 | R | OPT 850 | OPT 005 | OPT 010 | OPT 302 | ||

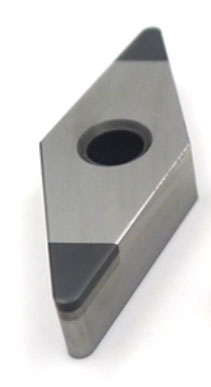

| VNGA160402 | 9,525 | 4,76 | 3,81 | 0.2 | ||||

| VNGA160404 | 9,525 | 4,76 | 3,81 | 0.4 | ★ | ||||

| VNGA160408 | 9,525 | 4,76 | 3,81 | 0.8 | ★ | ||||

| VNGA160412 | 9,525 | 4,76 | 3,81 | 1.2 | |||||

| VNGA220408 | 12.7 | 4,76 | 5.16 | 0.8 | |||||

| VNGA220412 | 12.7 | 4,76 | 3,81 | 1.2 | |||||

| VNGA160404-2 | 9,525 | 4,76 | 5.16 | 0.4 | ★ | ||||

| VNGA160408-2 | 9,525 | 4,76 | 5.16 | 0.8 | ★ | ||||

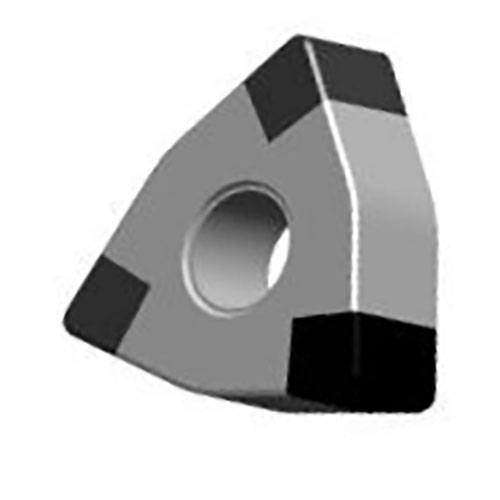

| Form setzen | Typ | Dimensioun (mm) | Grad | |||||||

| L | ¢IC | S | ¢d | r | OPT 850 | OPT 005 | OPT 010 | OPT 302 | ||

| WNGA06T304 | 6.5 | 9,525 | 3,97 | 3,81 | 0.4 | ★ | |||

| WNGA080408 | 8,69 | 12.7 | 4,76 | 5.16 | 0.8 | ★ | ||||

| WNGA080412 | 8,69 | 12.7 | 4,76 | 5.16 | 1.2 | ★ | ||||

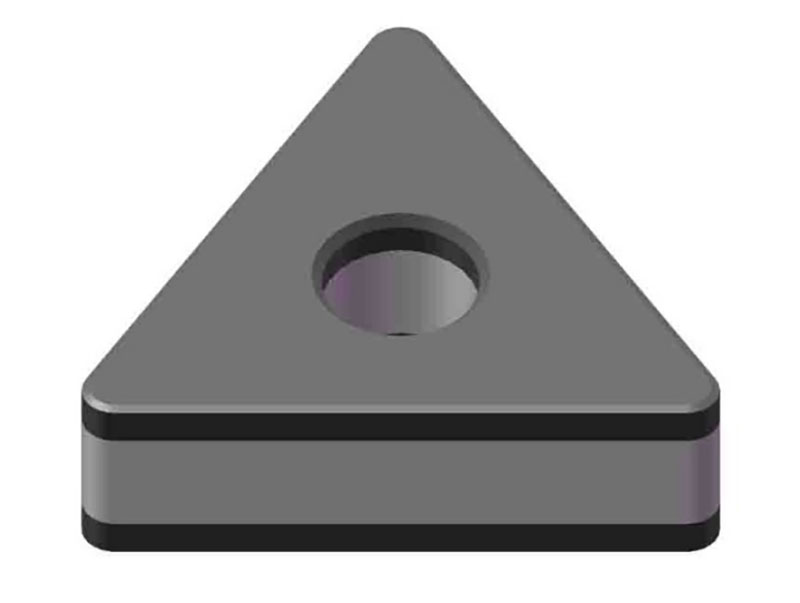

| Form setzen | Typ | Grad | |||||||

| d | s | d1 | R | OPT 850 | OPT 005 | OPT 010 | OPT 302 | ||

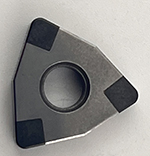

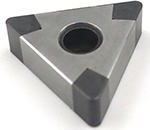

| TNGA160402 | 9,525 | 4,76 | 3,81 | 0.2 | ||||

| TNGA160404 | 9,525 | 4,76 | 3,81 | 0.4 | 〇 | ★ | |||

| TNGA160408 | 9,525 | 4,76 | 3,81 | 0.8 | 〇 | ★ | |||

| TNGA160412 | 9,525 | 4,76 | 3,81 | 1.2 | 〇 | ★ | |||

| TNGA160416 | 9,525 | 4,76 | 3,81 | 1.6 | |||||

| TNGA220404 | 12.7 | 4,76 | 5.16 | 0.4 | |||||

| TNGA220408 | 12.7 | 4,76 | 5.16 | 0.8 | 〇 | ★ | |||

| TNGA220412 | 12.7 | 4,76 | 5.16 | 1.2 | 〇 | ★ | |||

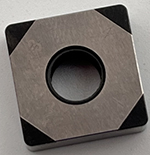

| Form setzen | Typ | Grad | |||||||

| d | s | d1 | R | OPT 850 | OPT 005 | OPT 010 | OPT 302 | ||

| SNGA090304 | 9,525 | 3.18 | 3,81 | 0.4 | ★ | |||

| SNGA090308 | 9,525 | 3.18 | 3,81 | 0.8 | ★ | ||||

| SNGA120404 | 12.7 | 4,76 | 5.16 | 0.4 | ★ | ||||

| SNGA120408 | 12.7 | 4,76 | 5.16 | 0.8 | ★ | ||||

| SNGA120412 | 12.7 | 4,76 | 5.16 | 1.2 | |||||

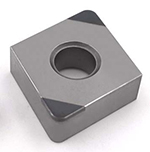

| Form setzen | Typ | Grad | |||||||

| d | s | d1 | R | OPT 850 | OPT 005 | OPT 010 | OPT 302 | ||

| CNGA09T302 | 9,525 | 3,97 | 3,81 | 0.2 | ★ | |||

| CNGA09T304 | 9,525 | 3,97 | 3,81 | 0.4 | ★ | ||||

| CNGA09T308 | 9,525 | 3,97 | 3,81 | 0.8 | |||||

| CNGA09T312 | 9,525 | 3,97 | 3,81 | 1.2 | |||||

| CNGA120402 | 12.7 | 4,76 | 5.16 | 0.2 | ★ | ||||

| CNGA120404 | 12.7 | 4,76 | 5.16 | 0.4 | ★ | ||||

| CNGA120408 | 12.7 | 4,76 | 5.16 | 0.8 | |||||

| CNGA120412 | 12.7 | 4,76 | 5.16 | 1.2 | |||||